Lindner Atlas 5500 ASI Shredder Refurbishment

Blaker Engineering recently refurbished a Lindner Atlas 5500 ASI shredder at our West Sussex workshop.

The machine operates in a demanding processing environment and had experienced wear in key working areas.

Kubota Digger Boom Arm Repair

A Kubota digger boom arm section was received at Blaker Engineering’s West Sussex workshop with a cracked and distorted pin boss, the critical pivot point connecting the boom to the rest of the machine. This project demonstrates Blaker Engineering’s expertise in plant repairs, including welding, machining, and fabrication.

Eddy Current Separator Rotor Refurbishment

Ford Tractor Axle Repair – Sussex, UK

Blaker Engineering was commissioned to replace a worn pivot ball in the front axle of a Ford tractor. The axle’s previous modification had left the swivel ball slightly out of alignment. A precision repair was required to restore correct geometry and ensure reliable operation.

Inclined Trough Auger for Metal Processing Plant, Kent, UK

Blaker Engineering was commissioned to designe and fabricate a bespoke inclined trough auger that integrates with existing equipment, improving overall process efficiency and supporting reliable, continuous operation.

Our HGV axle repair work has increased fourfold

We've been super busy with our axle repair work, which has increased fourfold over the last couple of months. The threads on this trailer axle were more or less destroyed! So, we put the axle into our lathe, machined off the old threads and then welded, dressed and re-machined the new threads.

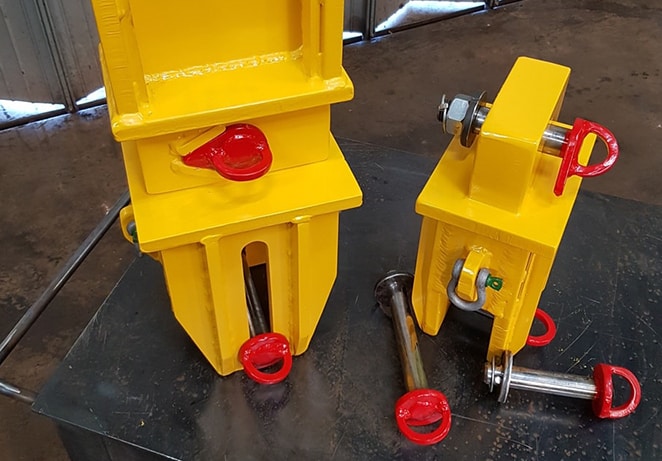

Creation of a bespoke forklift attachment

We've recently designed and fabricated a bespoke forklift attachment for a local company that specialises in injection moulds.

Emergency repair work metal fragmentiser mill

It was all hands to the pump to fix an emergency breakdown for our customer in Southern Ireland when their metal fragmentiser mill failed.

Fabricating a flywheel for a 1902 Oldsmobile

We’ve just finished fabricating a new flywheel for a 1902 Oldsmobile using the original as a pattern. We thrive on this kind of work and love to keep history alive.

Upgrading traction trailer wheel hubs to Timken roller bearings

A recent conversion of wheel hubs on a traction trailer, plain bearings to Timken roller bearings. The original bushes were broken and pressed into the wheel hubs.

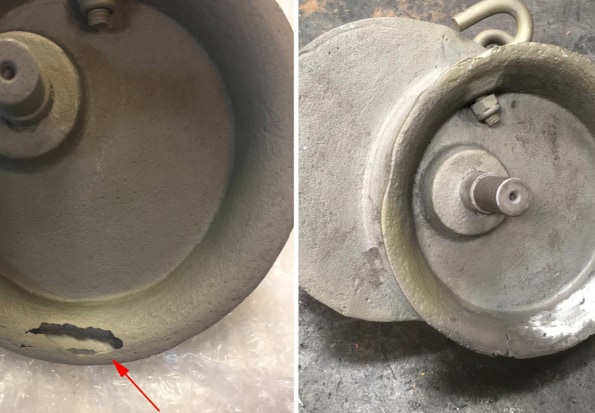

Repairs to ECS Rotor for a Recycling Centre in London

Our first task was to visually inspect the ECS rotor.

We soon realised that the drive pulley was damaged and there was evidence of the drum catching on the rotor.

Repairs to Bano shredder shaft - a big challenge!

This repair was big due to the physical size of the shredder shaft - a whopping 6.5 metres long! We remachined the bearing surfaces on both ends of the shaft and fitted new bearings.

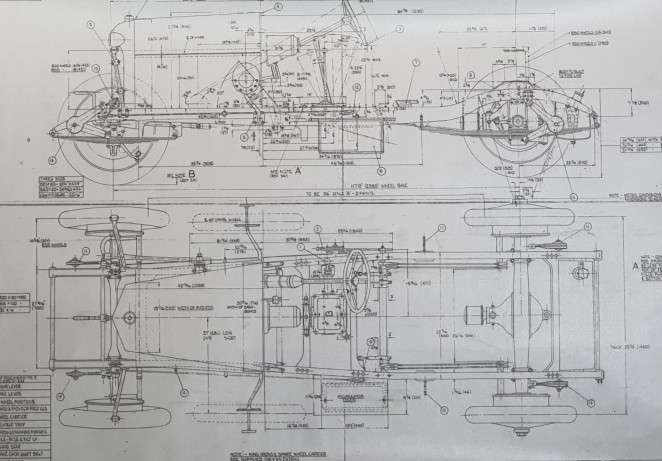

Repairs to a vintage chassis 1896 Peugeot Type 9 Car

The Peugeot type 9 was built by Pahard et Levassor under licence from Daimler and sold to Peugeot.

Repairs made to Dehaco & Liebherr Grabs

We’ve been super busy refurbishing scrap metal handling grabs for our metal recycling clients.

Repair and refurbishment work to Eddy Current Rotor

Due to the extent of damage to the Eddy Current rotor, this repair required significant fabrication work.

Urgent repairs to an Eddy Current rotor in the East Midlands

Our latest challenge was to repair a 1000mm wide Eddy Current as a matter of urgency.

Helping the UK transport network during COVID19

Repairing and straightening axles, to machining new parts during COVID19

Straightening and repairing a 1926 Bentley Chassis

Supporting client in the process of converting his classic 1926 Bentley tourer into a racer - a really exciting project.

Blaker keeps New Zealand traction engine rolling

New collar spacers plasma cut for visiting 8nhp Burrell steam engine

Repairs to vintage exhibit at Brooklands Museum

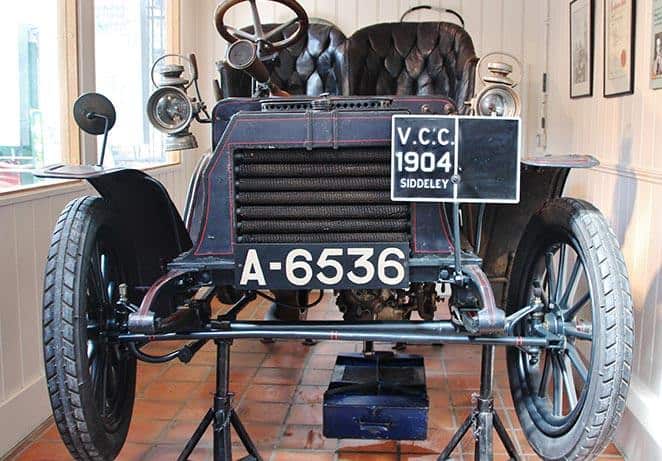

Welding repairs to 1904 Siddeley 2-seater tourer ‘Daisy’